| DE / INT: | +49 - (0)36453 - 744-0 | US: | +1 707 4810216 |

| info@layertec.de | ussales@layertec.com |

Metal-Dielectric Coatings

In general, all layer systems consisting of metals and dielectric layers can be called “metal dielectric coatings”. The most familiar ones are metal-dielectric filters consisting of transparent metal layers which are separated by a dielectric layer. These filters are characterized by extremely broad blocking ranges which result from the reflectivity and absorption of the metallic layers. The spectral position of the transmission band is determined by the optical thickness of the dielectric spacer layer.

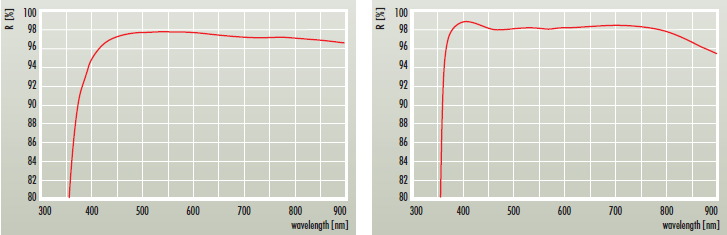

Here we want to draw the attention of the reader, however, to metal-dielectric reflectors. Metals and metallic coatings show an extremely broadband natural reflectivity which is, however, restricted to about 90% in the UV spectral range (aluminum), 96% in the VIS (silver) and 99% in the NIR (gold and silver). Moreover, most of the metals must be protected by dielectric coatings to overcome limitations of chemical (silver) or mechanical stability (aluminum, silver, gold).

More strictly speaking, almost all metallic mirrors are metal-dielectric coatings. The protective coatings always influence the reflectivity of the metals. Single dielectric layers of any thickness lower the reflectivity in most parts of the spectrum. However, multilayer coatings on metals can increase the reflectivity of the metallic coating. The bandwitdth of enhanced reflectivity can also be optimized for extremely broad spectral ranges as can be seen in the figure below.