| DE / INT: | +49 - (0)36453 - 744-0 | US: | +1 707 4810216 |

| info@layertec.de | ussales@layertec.com |

Metallic Coatings

Metals are the most common materials for mirror fabrication. Polished metals, especially gold, copper and bronze, were used as mirrors already in the ancient world. In the middle ages, mirrors with relatively constant reflectivity in the visible spectral range were fabricated using tin foils and mercury which were put on glass. The era of thin film metal coatings on glass began in the 19th century when Justus von Liebig discovered that thin films of silver can be manufactured using silver nitrate and aldehyd.

Mirrors for applications in precision optics and laser physics are produced by evaporation or sputtering techniques. LAYERTEC uses magnetron sputtering for the fabrication of metallic coatings. This results in coatings with extremely low straylight losses. Moreover, also transparent, i.e. very thin metal coatings can be produced with high accuracy. For detailed information about our metallic mirrors and neutral density filters please consult our catalog.

For further information about silver mirrors you can also consult our Silver mirrors for fs applications section.

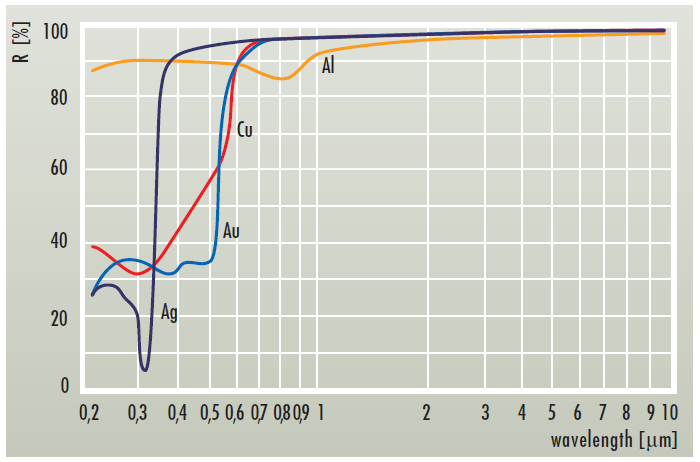

The chart below gives an overview about the reflectivity of the most common metals.

Hints for use

In the following we give some hints for the use of these metals and about the role of protective coatings:

Silver

- Highest reflectivity in the VIS and NIR

- LAYERTEC produces protective layers by magnetron sputtering. These layers with very high packing density make silver mirrors as stable as mirrors of other metals (e.g. aluminum). Lifetimes of 10 years in normal atmosphere were demonstrated.

- The use of protective layers is mandatory, because unprotected silver is chemically unstable and soft

- See separate data sheets in our catalog

Gold

- Similar reflectance as silver in the NIR

- Chemically stable, but soft

- Protective layers are necessary to make gold mirrors cleanable

- We recommend to use protected silver mirrors instead of protected gold, because the sputtered protective layers overcome the insufficiency of silver and make it a better choice because of the broader wavelength range, the slightly higher reflectivity and the more favourable price.

- See separate data sheet in our catalog

Aluminum

- Relatively high and constant reflectance in the VIS and NIR

- Highest reflectance in the UV

- Surface oxide layer absorbs in the deep UV

- A protective layer is recommended, because aluminum is soft

- See separate data sheet in our catalog