| DE / INT: | +49 - (0)36453 - 744-0 | US: | +1 707 4810216 |

| info@layertec.de | ussales@layertec.com |

Capabilities

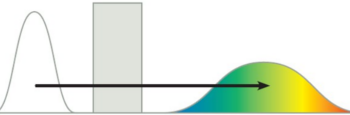

Our company combines a precision optics facility and a variety of coating techniques (magnetron and ion beam sputtering, thermal evaporation, ion assisted e-beam evaporation) which enables LAYERTEC to control the quality of the optical components over the whole production process from grinding, polishing and cleaning of the substrates to the final coating process.

Today, a staff of over 400 employees are working in the precision optics facility and coating laboratories of LAYERTEC. 40 coating machines are available to cover the wavelength range from the VUV to the NIR using sputtered and evaporated coatings such as fluorides and oxides, metallic and metal-dielectric coatings.

LAYERTEC offers the full spectrum of design and manufacturing for a high flexibility to customize optical components for special applications with an optimum of coating performance and cost efficiency. The variety in size and technology of our coating equipment allows a high-volume fabrication for series products as well as a flexible prototype manufacturing for R&D groups in the industry and for research institutes.

If you are searching for any particular product, please visit our online shop.