| DE / INT: | +49 - (0)36453 - 744-0 | US: | +1 707 4810216 |

| info@layertec.de | ussales@layertec.com |

Components for Er:YAG Lasers and the 3μm region

Components for Er:YAG Lasers

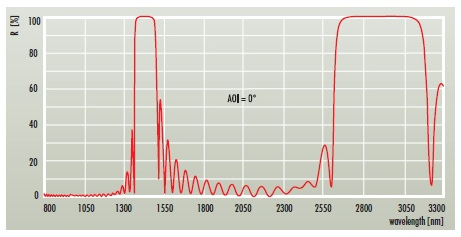

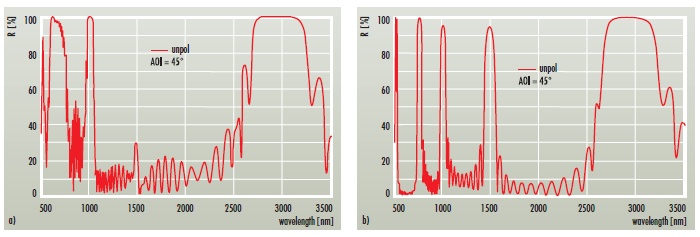

- HR cavity and turning mirrors

- Reflectivity: R > 99.9 % at AOI = 0°, R > 99.8 % at AOI = 45° for random polarized light

- High damage thresholds (400 J/cm2 at 400 μs)

- Pump mirrors with high transmittance between 800 nm and 1100 nm for pumping with a Nd :YAG laser or a diode laser

- Dual wavelength turning mirrors, e. g. HRr (45°, 2940 nm) > 99.5 % + Rr (45°, 630 – 655 nm) > 95 %

- Beam splitters and beam combiners, e. g. HRr (45°, 2940 nm) > 99% + Rr (45°, 630 – 655 nm) < 20 %

- These components allow to use a He-Ne laser or a diode laser between 635 nm – 655 nm for the alignment of the optical system

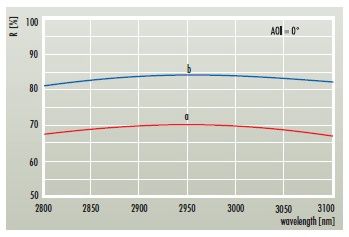

Output Couplers and Lenses

- Output couplers with precisely adjusted degrees of reflectivity (tolerances of ± 1 % at reflectivities between 70 % and 90 %)

- AR coatings with residual reflectivities R < 0.2 % on the rear side of output couplers as well as on lenses and windows made of sapphire, undoped YAG, CaF2 or Infrasil®

- (a) R = 70 % and

- (b) R = 84 %

Components for other Lasers around 3μm

The fundamental effect which is especially used for the medical application of lasers emitting light between 2.6 – 3.4 μm is the strong absorption of water in this wavelength range. Between 2.6 μm and 2.8 μm the absorption of water is still stronger than at 2.94 μm (Er:YAG laser) which makes lasers working in this wavelength range (e. g. the Er:Cr:YSGG laser) promising candidates for future applications.

However, the strong absorption of water is also the most serious problem with respect to laser damage. Therefore, it is essential to keep the layer system free of water. LAYERTEC uses magnetron sputtering for the production of coatings for the 3 μm region. The high atomic density of sputtered layers which is close to that of bulk material suppresses the diffusion of water into the layer systems.

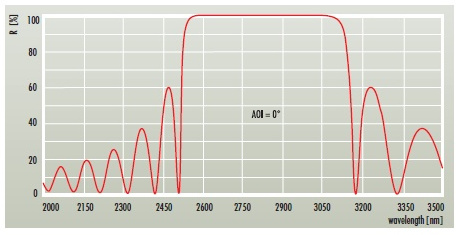

This enables LAYERTEC to offer also coatings for the critical 2.6 – 2.8 μm region. Figure 5 shows as an example a HR mirror centered at 2.8 μm with a reflectivity R > 99.7 %.