High quality fused silica components

Premium Quality Substrates

Premium quality substrates for special laser applications as Cavity Ring Down Time Spectroscopy or EUVmirrors are characterized by:

- Exact geometry and shape

- Surface roughness

- Surface form tolerance

- Number of defects on the polished surfaces.

LAYERTEC has optimized the polishing procedures for all of these parameters. In the following we show some outstanding results which were achieved with fused silica and calcium fluoride.

Specifications

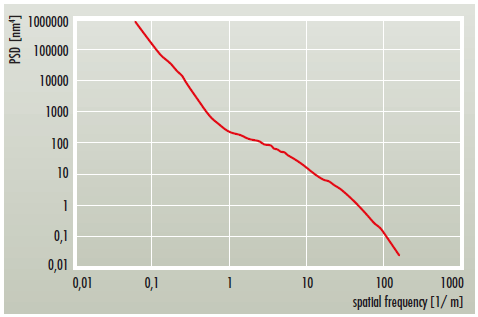

Surface Roughness

- RMS - roughness < 1.5 Å achieved for plane substrates of fused silica

- Similar results on smoothly bent spherical fused silica surfaces (depending on the ratio of diameter and radius of curvature)

- Very low scattering losses of the substrates even in the UV- range:

- TS = 2 x 10–5 at 248 nm (total backscattering)

- TS = 5.6 x 10–4 (total backscattering) and 7.5 x 10–4 (forward scattering) at 193 nm

Surface Form Tolerance

| Fused silica | Plane | λ/30 (633 nm) for diameters of 6.35 mm to 101.6 mm |

|---|

| Spherical | λ/30 (633 nm) for diameters < 51 mm |

|---|

Surface Quality

| Material | ISO 10110 (∅ 25 mm) | Approximately equivalent to MIL-O-13830 |

|---|

| Fused Silica | 5/ 1 x 0.014; L 1 x 0.0005 | Scratch-Dig 5-1 |